Industry 5.0 Starts Here

NUMEN AI is the evolution of facilities management and a leads the way to true Industry 5.0.

NUMEN AI unlocks unprecedented levels of efficiency in both humans and systems.

NUMEN AI draws on industry export knowledge, benchmarks and best practice combined with high quality Numen Data to advise 24/7/365.

NUMEN AI continuously monitors and guards. Built-in Machine Learning algorithms are able to detect anomalies and predict equipment failure and safety hazards.

A future beyond human ability

Peace of Mind, No Surprises

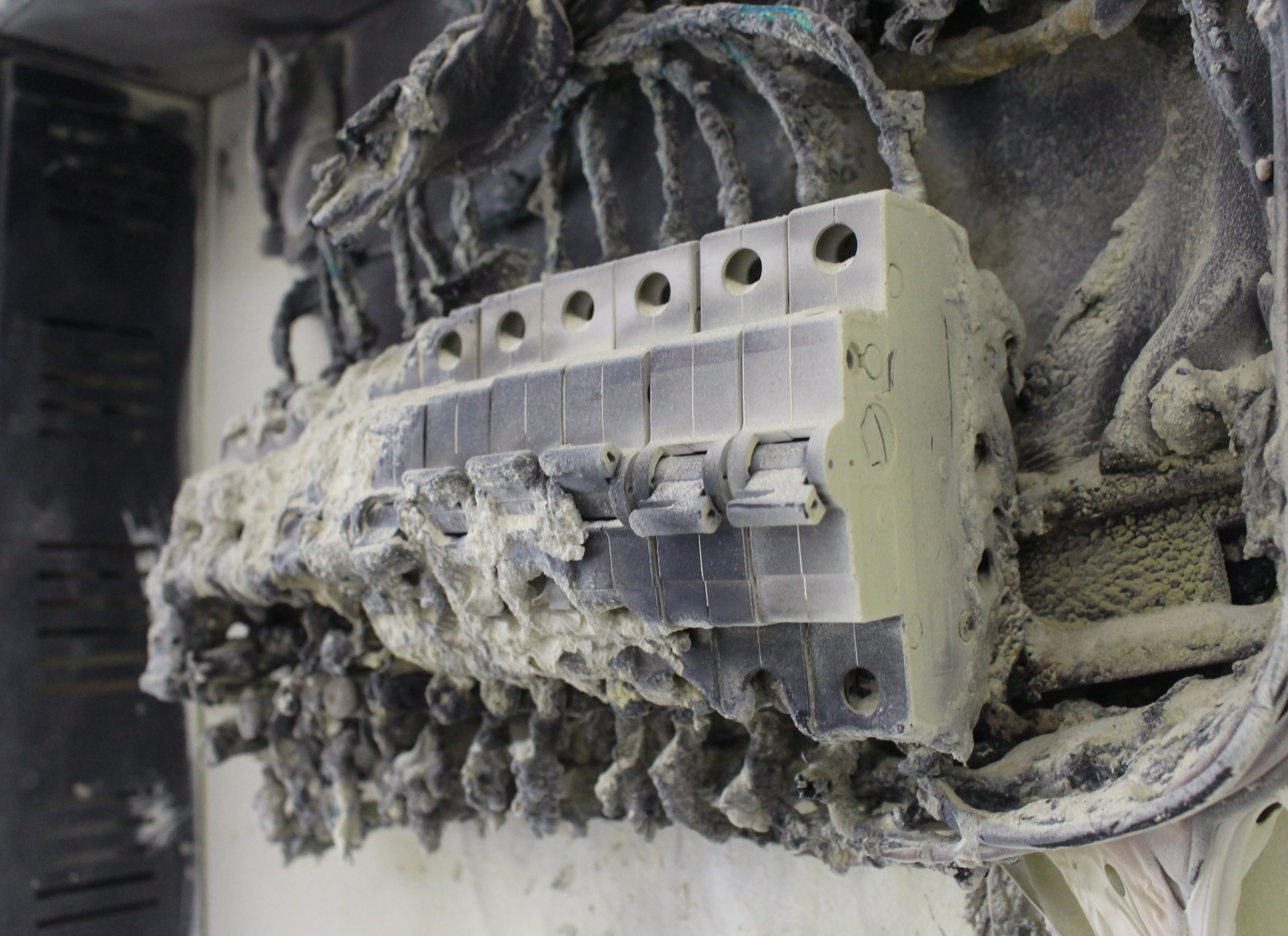

All facilities have hidden inefficiencies and risks that worsens over time. Many of these risks are overlooked and misunderstood.

Unbeknownst to most facilities managers, these risks will increase energy consumption, increase risks of fire and personal injury and will cause unexpected equipment failure, downtime and loss of production.

Currently, most engineers and facilities managers rely on their experience and instincts to understand and manage these risks. Unfortunately, even experienced personnel can not keep an eye on everything all the time.

Future facilities management will rely on AI to enhance human ability to ensure optimal facility efficiency and reliability. A future now known as Industry 5.0, beyond human ability.

Facilities not embracing this revolution will not only struggle to remain competitive in the market, but will find themselves under significant pressure to meet government mandated sustainability and efficiency targets.

NUMEN AI provides a future-proof AI platform that will continue to learn and evolve and provide facilities managers with peace of mind that lack of experience and knowledge will never result in catastrophic outcomes.

Energy Optimisation & Sustainability

Power Quality - The secret enemy of energy efficiency

Supply power quality is a problem area that is often overlooked. Bad power quality can lead to increased power consumptions, excess heat generation and reduction of equipment life.

- Analyse and report on power quality issues

- Simple and prioritised list of recommend corrective action

Fault Prediction & Detection

Detect anomalies and provide early warning of equipment failures

- Machine Learning algorithms continuously track equipment performance and notifies on detection of anomalies

- Sensitve monitoring provide early warning of equipment failure

Safety

Reduce the risk of heat build up, electrical fires and electrical shock

- Detects and locates electrical arcing

- Monitor over current causing heat build up but not tripping circuit protection

- Report on dangerous neutral currents

- Catch potential hazards early